Semi Conductor

Semi Conductor

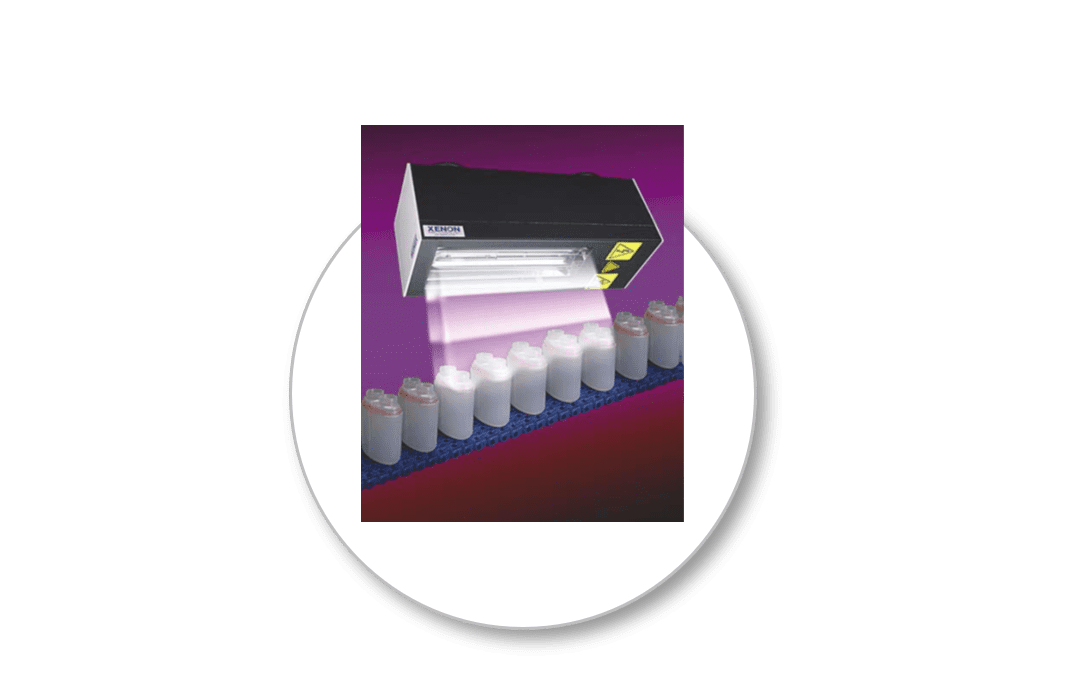

aNexus Xenon SteriPulse-XL RS-3000 Sterilization Systems

RS-3000 Sterilization Systems

The SteriPulse-XL Systems are high energy, pulsed UV light sterilization systems that have been shown to completely eradicate microorganisms and provide a higher rate of sterilization than continuous mercury UV exposure. A revolutionary xenon lamp at the heart of the system delivers high energy pulses of UV light that penetrate deeply to achieve unprecedented degrees of decontamination. The pulsed UV light process is environmentally benign since it does not create or use volatile organic compounds (VOCs) or create suspended airborne particulates.

APPLICATIONS

•Sterilizing or decontaminating food, medical devices, packaging materials, blood or pharmaceutical products

•Validate operating parameters for inline processing

FEATURES

•R&D Benchtop (Model RS-3000C) and inline processing systems available (Models RS-3000B and RS-3000M)

•Pulsed UV lamp delivers 505 joules/pulse (1.27 joules/cm²)

•Short pulses (360μs width) prevent excessive heat buildup and accomplish sterilization without overheating the product

•Front-panel operator control (Models RS-3000B and RS-3000C) or PLC control (Model RS-3000M)

•No toxic materials, such as mercury or microwaves are involved

PULSED UV LAMP

Rapid, high intensity, broad spectrum UV light emitted by the clear fused quartz lamp causes formation of Pyrimidone dimers in DNA, resulting in genetic damage to cells and their ultimate destruction. Types of damage induced by pulsed light are: (a) photolysis; (b) loss of colony-forming ability (death); (c) inability to support phage growth (enzyme inactivation) and (d) destruction of nucleic acid.

STERILIZATION CHAMBER The SteriPulse-XL Sterilization Chamber, with removable Lamp Housing, is detached from the Controller. Ozone is evacuated to ensure EPA ozone level compliance in the workplace. Forced air evacuation is in the range of 1-4 volumes per minute to ensure no heat buildup within the chamber during sterilization. The Chamber does not evacuate air borne pathogens nor introduce air borne pathogens into the Chamber while the system is in the ON cycle. Microbe filters, ozone resistant, are used at both the inlet and outlets of the ventilation path to ensure containment of air borne pathogens. The Chamber has an interlocking door for lockout during the sterilization ON cycle. The door interlock switch is connected with the safety interlock switches in the Controller. The Chamber and insert are made of stainless-steel construction for ease of sterilization and disinfection. This construction also insures the Chamber is able to withstand UV light and heat conditions, experienced under normal operating conditions.