Semi Conductor

Semi Conductor

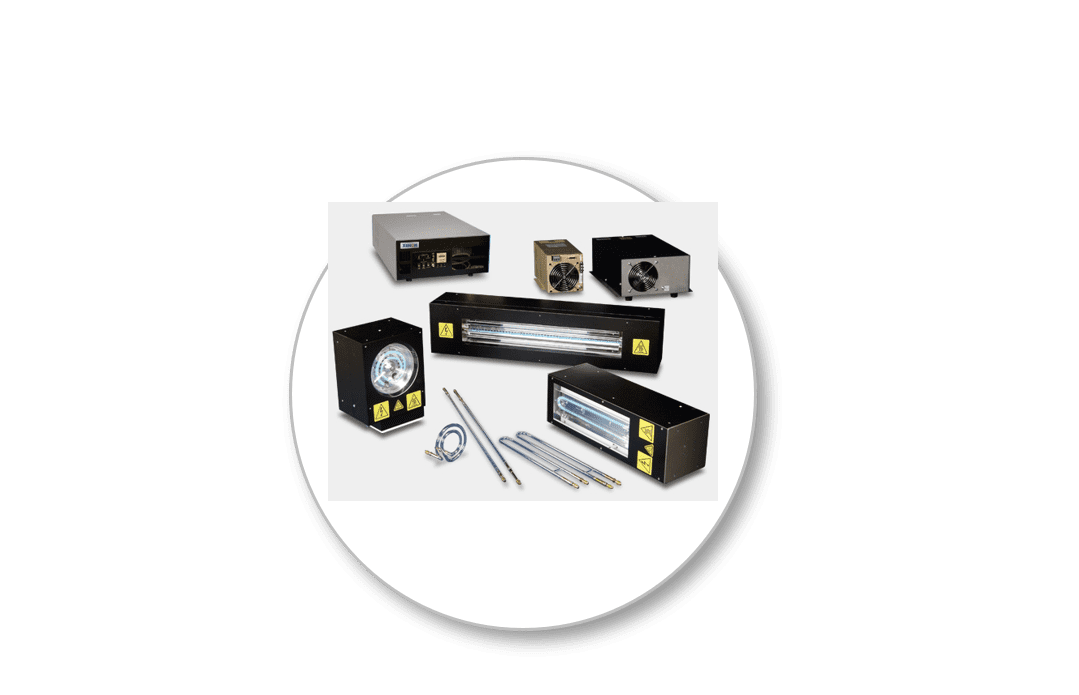

aNexus XENON RC-800

The aNexus XENON RC-800 offers one of the safest, most flexible, highest-performing curing solutions available anywhere. These systems are proven worldwide in curing applications as diverse as optical discs, medical devices, pharmaceutical packaging, plastic bonding, wood coating, and many more.

If your application can benefit from energy efficient, rapid, cool curing at lower operating cost, we invite you to take a closer look at the new XENON RC-800.

Unique CoolCureXL technology:

The RC-800 features XENON’s unique CoolCureXL Pulsed Light technology, which delivers rapid curing without excessive heat. It’s a significant improvement over mercury UV systems for the most demanding application

Wide range of options for process flexibility:

Because the underlying technology is more versatile, the RC-800 Series offers more choices

than mercury UV systems. You can choose from a wide range of high intensity pulsed UV lamps, housings and other options that let you mix-and-match a curing system to perfectly fit your application. You can use RC-800 systems for continuous inline and index curing applications.

One of the keys to effective curing is matching the UV light “footprint” to the target size and shape. That’s why XENON offers more choices in lamp shapes and sizes. Over the years, XENON has developed a wide array of lamp styles — so you can precisely match the optical footprint of the lamp to your needs. And we’re constantly adding to our lamp selection to meet evolving customer requirements.

In addition, all RC-800 lamps offer a range of pulse rates and energies (up to 100 pulses per second; up to 507 joules per pulse), so they can be matched to a wide range of throughput requirements. Almost unlimited pulse sequencing can be user programmed, allowing an optimum match of UV light delivery to the target.