Semi Conductor

Semi Conductor

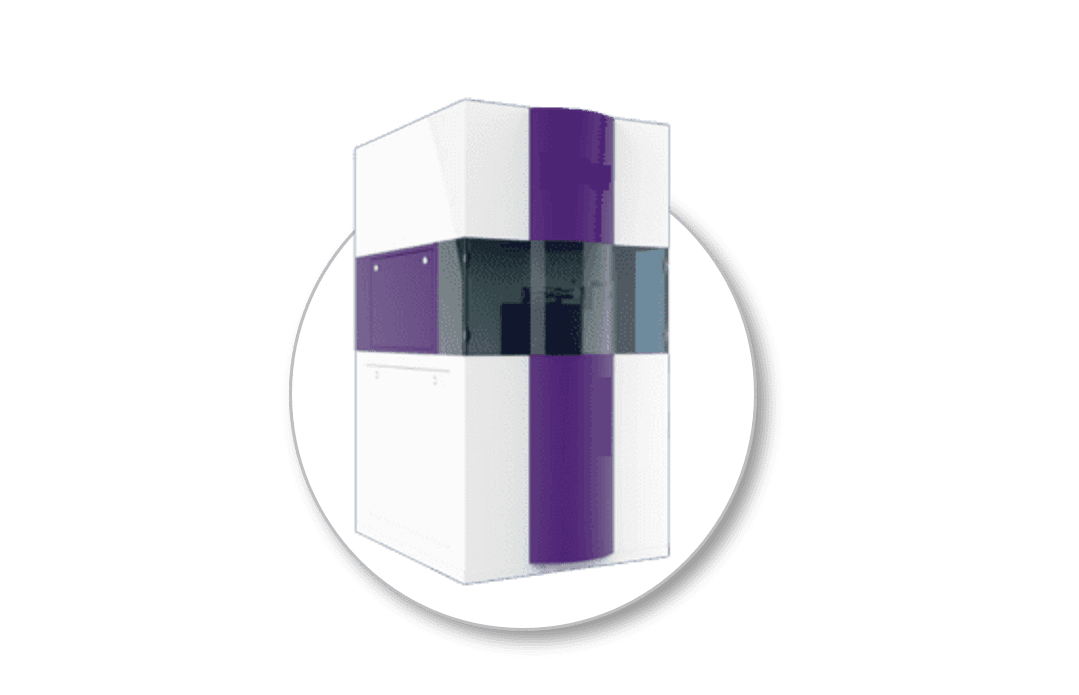

aNexus High-Precision Electron Beam Lithography (EBL) System for Advanced Semiconductor & Quantum Research

Our Electron Beam Lithography (EBL) System is engineered for high-resolution, high-speed patterning on semiconductor wafers, making it ideal for cutting-edge research and industrial applications across Southeast Asia.

Equipped with a field emission gun (FEG) and a built-in high-speed graphics generator, this advanced EBL tool enables ultra-precise lithography at nanometer scales. It features a laser interferometer-based motion stage, delivering exceptional accuracy in large-area patterning, high-precision stitching, and overlay alignment, essential for next-generation device fabrication.

This EBL system supports a wide range of innovation-driven industries, including:

- Semiconductor manufacturing

- Microelectronics and photonics

- Quantum computing and nanotechnology

- Advanced materials development

- Fundamental and applied physics research

Key Features of the Electron Beam Lithography (EBL) System

1. Advanced Laser Interferometer Stage

Our EBL system is equipped with a high-precision laser interferometer stage designed for large-stroke movement, delivering exceptional accuracy in stitching and overlay alignment. This ensures reliable pattern placement across a wide writing area—ideal for advanced semiconductor and nanofabrication applications.

2. High-Resolution Field Emission Gun (FEG)

At the core of the system is a high-resolution field emission gun, which provides a stable, focused electron beam—critical for achieving superior lithography quality and consistent pattern fidelity, even at nanometer scales.

3. Ultra-High Resolution with High-Speed Scanning

Engineered for both ultra-high resolution patterning and ultra-fast scanning speeds, this system enhances throughput without compromising accuracy. It is an optimal choice for institutions and manufacturers working on next-generation microelectronics, photonic devices, and quantum research.

Stage Specifications

| Standard Equipment | Laser Interferometer Stage |

| Stage Travel | ≤105 mm |

Electron Gun and Imaging Specifications

| Schottky Field Emission Gun | Acceleration Voltage 20V ~ 30kV; Side Secondary Electron |

| Image Resolution | Detector and In-Lens Electron Detector |

| Beam Current Densit | > 7000 A/cm² |

| Minimum Beam Spot Size | ≤2 nm |

Lithography Specifications

| Electron Beam Shutter | Rise Time < 100 ns |

| Writing Field | ≤500×500 um |

| Minimum Single | < 15 nm (dependent on process conditions) |

| Exposure Line Width | ≤20 MHz |

Graphics Generator Parameters

| Control Core | High-performance FPGA | Minimum Dwell | 10 ns |

| Maximum Scan | 50 MHz | Time Increment | GDSII、DXF、BMP, etc. |

| Speed | 20-bit | Faraday Cup Beam | Included |

| D/A Resolution | 10 um~500 um | Current Measurement | Optional |

| Supported Writing | 5 V TTL | Proximity Effect | Optional |

| Scan Modes | Sequential (Z-type), Serpentine (S-type), Spiral, and other vector scan modes | ||

| Exposure Modes | Supports field calibration, field stitching, overlay, and multi-layer | ||

| External Channel | automatic exposure | ||

Optional Accessories

-Companion UPS (Uninterruptible Power Supply)

-Companion Active Vibration Isolation Table, with a minimum natural frequency of 2Hz